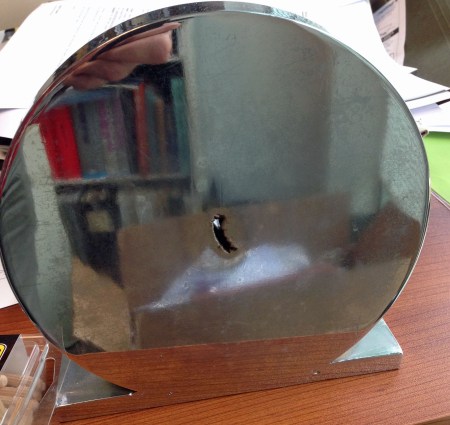

The majority of defects encountered in steel bars in our shops are found on the surface. Internal defects can also be encountered, and we posted about central burst (chevron) defects here. This post describes Pipe Steel.

Definition: A central cavity formed by contraction of the metal during solidification is called pipe.

When this cavity is found in wrought or cast products, this is also called pipe.

In the days of ingot casting, the location of the shrinkage cavity was controlled by ingot mold design and the addition of hot tops to assure that after cropping the material containing the void off, there would remain sufficient sound material to roll into product.

Today with modern computer controlled billet and bloom casting processes, pipe steel and center porosity is very seldom encountered.

Recently a question was asked about centerline defects on cast billets in one of my LinkedIn Groups.

“hello can any one tell us why some times whe have holes along the center of the billets just casted thanks”

Despite a lack of specifics about grade, deoxidation, and many other factors, we can make some comments based on the fact that this is continuously cast billets according to question.

Here are my comments addressing the continuous billet casting process and how it can be implicated in the creation of centerline voids (pipe steel defects).

The three key parameters in the casting process that are most likely to result in centerline pipe are

- Casting speed

- Superheat

- Electromagnetic Stirring. EMS amperage and frequency (Together they drive intensity.)

1. Casting Speed– Incorrect casting speed can result in pipe/ centerline looseness/ porosity. This can be aggravated by issues with mold level control. Slow down your casting speed to get sufficient solidification.

2. Superheat is critical to maintaining the proper fluidity and solidification dynamics in the mold. Liquid metal shrinks in three steps; 1) volume decreases the liquid cools goes from the pouring temperature to the freezing temperature; 2) volume decreases as the metal solidifies. This is reinforced by the driving out of dissolved gases as the metal freezes; 3) the metal shrinks as it cools from solidification temperature to ambient temperature.

3. Electromagnetic Stirring (EMS)– If you macroetch transverse sections of the billets and still see columnar rather than equiaxed grain structure in the cast billet, it is a sign that the EMS is ineffective.

There are a host of other operating parameters as well as chemistry and processes that can contribute to porous centers or central cavity pipe steel defects. Here is a list of questions to help address these:

Do you have adequate cooling water through the molds? Are you running EMS? What is the metallurgical distance on this caster? What is the mold level control? Evidence of turbulence into the mold? Meters per minute for casting speed? Shrouding status on nozzles? What was superheat? What was water flow?

Do you have chemistry in control, steel deoxidized, so that the large void is a result of solidification shrinkage, not divorce of gas from the liquid steel? What is grade? What was deoxidizer?

Continuous casting of steel is a complex process with a large number of operating parameters and processes that need to be in close control. Understanding how these parameters can impact the final product is critical to eliminating defects that result from lack of control.