This 4 minute video was produced by a British high school in cooperation with a film-maker and local police authorities.

The fact that the cars are driving on the left helps it make more of an impression on those of us who drive on the right side of the road here in North America.

This is a graphic, but essential reminder to all of us to reconsider our choices of distractions while behind the wheel. Or operating machinery and equipment.

Choices have consequences.

Do we really need to answer that cellphone, right now?

Do we really need to send that text message? Really?

Please don’t answer these questions until after you watch the video.

Then, by all means, please share your opinion.

Month: October 2009

Actions always speak louder than words.

Here’s what GE’s CEO, Jeffrey Immelt, told the Detroit Press Club back in June:

“We would do much better to observe the example of China. they’ve been growing fast because they invest in technology and they make things. They have no intention of letting up in manufacturing in order to evolve into a service economy.”

This is the same GE that closed lighting manufacturing plants here in Ohio.

Who decided to close our manufacturing plants here in Ohio, Jeff?

Who decided not to reinvest money here in Ohio to “make things?”

Who decided that absorbing say, $500 000 000 in restructuring costs to close a small number of plants is better than spending, $40-45 000 000 in reinvestment to make new CFL technology light bulbs here in the USA?

Where do you suppose US workers might get those “green manufacturing jobs” if you’re not building the factories to make light bulbs here in the US?

So before you reach for that that “green” CFL lightbulb with the GE logo on it, remember the hypocrisy of Jeffrey Immelt, “20 % of US jobs should be manufacturing jobs,” while closing plants and failing to reinvest to make these “green products” here in the US.

When you see that ad on TV from GE to “Buy Green,” what they are really saying is “BUY FROM CHINA.”

Note to Jeff Immelt: US labor productivity is among the highest in the world. Our factories are subject to stringent regulations to assure that we protect the environment. Why would you not want to make this staple “green” product here?

Just wondering.

I wanted to write a post about how manufacturing in North America is still a vital part of our, and the world’s, economy. While I was looking for facts and data, I came across this gem of a blog authored by Dr. Mark J. Perry, Professor of Finance and Business Economics at the School of Business, University of Michigan- Flint, on his blog Carpe Diem. He makes a great case.

Enjoy!

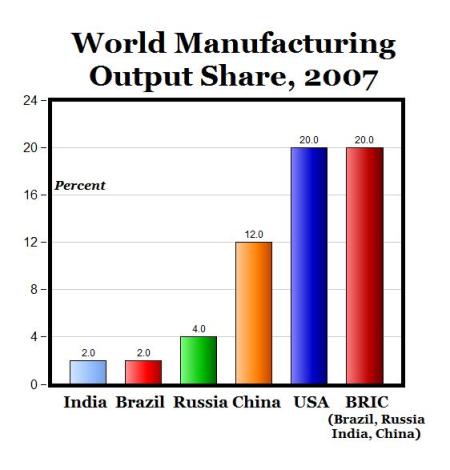

The chart above shows manufacturing output of selected countries and the BRIC countries, as a share of world manufacturing output in 2007, using United Nations data via the BLS (I haven’t been able yet to find comparable data for 2008). It’s interesting that U.S. factories produced almost twice as much output in 2007 as China, and the U.S. produced an amount equivalent to the total manufacturing output of the four BRIC countries combined (Brazil, Russia, India and China).

And as a Cato Study concluded in 2007, “Reports of the death of U.S. manufacturing have been greatly exaggerated.”

And as David Brooks wrote in 2008, “Instead of fleeing to Asia, U.S. manufacturing output is up over recent decades. As Thomas Duesterberg of Manufacturers Alliance/MAPI, a research firm, has pointed out, the U.S.’s share of global manufacturing output has actually increased slightly since 1980.”

According to the Federal Reserve data, the U.S. produced almost $3 trillion of industrial output in 2008, measured in 2000 dollars (or about $3.7 trillion in 2008 dollars). In other words, if the U.S. manufacturing sector had been counted as a separate country, it would have been tied with Germany as the world’s fourth largest economy, behind the U.S. (non-manufacturing), Japan, and China, and ahead of the entire economies of France, U.K., Italy and Russia (data here).

Bottom Line: The U.S. is still the world’s largest manufacturer.

PMPA is actively working on Capitol Hill,

as well as with the Administration and business groups, to extend the Net Operating Loss (NOL) carry-back tax provision to support companies who will incur losses in 2009.

Through our lobbying firm, The Franklin Partnership, we are hearing that Senate Democrats are considering adding a four-year net operating loss carry-back provision to bills being considered this week. The tax provision would enable unprofitable companies to obtain immediate cash refunds on taxes they paid over the prior four years, instead of the usual two years.

The proposal floated by Senate Majority Leader Harry Reid (D-NV) and Senate Finance Chairman Max Baucus (D-MT) falls just short of our hope to extend refunds to cover the previous five years. However, this is a VERY important step needed to help small manufacturers who are suffering today and inject immediate cash in to their businesses. Extending the loss carry back period to 5 years will allow small businesses to recover cash that could be used to help pay debt or invest in equipment and people in this difficult time.

Please support PMPA’s efforts on the NOL provision and contact your Senators and Representative, by clicking here, to urge them to support extending the NOL carry-back provision to five years and covering losses incurred in 2009.

Its really up to you.

http://capwiz.com/pmpa/issues/alert/?alertid=14223241

Now that manufacturing is two months into expansion, September 2009 ISM Report , our short list of long delayed purchases will once again be under serious consideration. Here are 6 reasons to throw out your old list and start a new one.

- It’s not the old economy. It’s no longer business as Mayberry RFD anymore.

This is your grandfather's economy.

What you were looking at before the recession was what you needed for a prerecession economy. That’s not today. - Your suppliers have been busy. Making improvements, reducing costs, increasing capabilities of their products. Machines, tools, and software especially. What may have been a “lock” 6 months ago may in fact be a dog compared to currently available offerings.

- Your customers have changed. Some have gone away, and some have lost your trust. Do you really want to buy something that is single purpose for an account that you can’t trust?

- Your market focus has changed. The lessons your team learned in this downturn are what your customers will continue to buy from you and what they didn’t (won’t). Maybe what you were planning on buying was to produce something for the stuff that hasn’t been selling these days…

- Your needs are really, really different today. When you first made that shopping list, your planning assumptions included readily available bank credit, solvent customers, 16 million plus auto sales in US and full employment in your shops. Today availability of credit is iffy, customers that remain are slow to pay, and auto sales are not likely to top 12 million. The headcount in your enterprise has been drastically reduced. What you wanted then is NOT necessarily what you need today.

- It won’t be appropriate in your new structure. How will what you wanted back in the good ol’ days be appropriate in your shop today with half your staff on layoff and the remaining staff working OT?

Is now the time to be faithful to a dusty old procurement plan based on a vanished Mayberry RFD economy?

We have just survived the Terminator economy. Tell me again why you want to buy Andy of Mayberry’s fishing pole?

Which items on your list remain viable, and what new ones will you be adding?

![]()

The AP reported that “Ford Motor Co. said Tuesday it will add 4.5 million older-model vehicles to the long list of those recalled because a defective cruise control switch could cause a fire. ”

Photo credit: NYTimes

“The latest voluntary action pushes Ford’s total recall due to faulty switches to 14.3 million registered vehicles over 10 years, capping the company’s largest cumulative recall in history involving a single problem.”

Here is a list of the latest affected vehicles: 1995-2003 Ford Windstar; 2000-2003 Ford Excursion diesel; 1993-1997 and 1999-2003 Ford F-Super Duty diesel; 1992-2003 Ford Econoline; 1995-2002 Ford Explorer; 1995-2002 Mercury Mountaineer; 1995-1997 and 2001-2003 Ford Ranger; and 1994 Ford F35 Motorhome vehicles.

Our relevant question: Are the defective parts, reportedly produced by Texas Instruments, produced here in North America? Or were these safety critical parts produced overseas in order to obtain the lowest globally available price?

Just answer the question, please.

Photo credit: NYTimes

And how to minimize them.

Upon heating, steel parts change volume as they change crystal structure (I’ll spare you the technical terms and details). When these heated parts are quenched, their internal crystal structure changes again, and that volume change is not necessarily sufficient to offset the change upon heating. This change of volume can cause dimensional distortion. The rule of thumb that I have used for medium carbon alloy steels is to expect a change in linear dimensions of about 0.125% maximum. That is, one eighth of a percent of the linear dimensions could be the change encountered from heat treatment and quench. It generally is less, but 0.125% gives me a rule of thumb to evaluate capability to hold dimensions after heat treat. What rule of thumb do you use to estimate part growth as a result of heat treat?

Warpage or shape distortion as a result of heat treat is different because it is usually a result of process and design issues rather than the expected phase changes of the material.

Here are 8 reasons steel parts can warp upon quench and tempering:

- Rapid heating.

- Overheating.

- Non-uniform heating.

- Non-uniform cooling.

- Non-uniform agitation.

- Water contamination in oil.

- Large changes of mass and section.

- Asymmetric features.

Rapid heating can cause stresses to develop in parts due to excessive temperature gradients. Overheating similarly lowers mechanical properties, potentially leading to parts sagging or creeping depending on orientation in the furnace. Non-uniform heating also creates differences in properties within the parts as well as leading to incomplete transformation products or hybrid structures upon quenching. Non-uniform cooling allows unbalanced stresses to develop during the quench, as does non-uniform agitation of quench medium. Often non-uniform heating or cooling result from the way parts are stacked or piled in the basket or on the belt such that gradients of temperture are created. Water contamination in oil. This is difficult to figure out, but in addition to warped parts, inconsistent hardness readings between parts or on the same part are a sign of this. Parts with large section changes or that have asymmetric features are also more likely to warp than parts with balanced and uniformly distributed mass, regardless of process control.

Choosing steels with higher hardenability (alloys rather than plain carbon steels), finer grain size, and paying attention to the details of loading, time at temperature, and quenchant delivery are all steps that can minimize warpage distortion, even when part design is less than optimum.

For the Precision Machining Industry, a strong case can be made that our sales are recovering.

PMPA’s Index of Sales of Precision Machined Products rose to 82, just one point below January’s high of 83.

This is an 11 percent rise in the sales index compared to August, and documents the 95 reporting companies in aggregate are showing a 26% recovery in sales compared to the 2009 year low of 65 in May, 2009.

Fifty-two percent (52%) of our particpants reported double digit sales increases in September.

The outlook for sales in the short term has stabilized, with only 19% of respondents expecting a decline in sales overthe next three months.

For almost a year, Tom Brady sat on the sidelines, working on his recovery. In the sixth week of this new season, he set an NFL record for touchdown passes in one quarter. What a comeback!

The Precision Machining Industry is still on the field despite being hamstrung last fall by the economic meltdown. Our performance continues to be 100% on time and zero ppm. We just need more time on the field. Comeback in progress!

See the full report.

We have open time on our machines. How can we help you?

So much for Change…

The Associated Press reports that “the Obama administration on Thursday declined to name China as a country that is manipulating its currency to gain unfair trade advantages.”

“The Treasury Department did say it has “serious concerns” about a lack of flexibility in the value of China’s currency against other currencies, and the country’s rapid accumulation of foreign exchange reserves including U.S. dollars.”

“The administration’s decision came in a report the Treasury is required to submit to Congress twice a year. Based on a 1988 law, the administration must designate countries judged to be manipulating their currencies to boost their exports to the United States or make U.S. products more expensive in overseas markets.”

Hmmmm…

Obama promised to take a tougher stance against China on trade issues

during his campaign for the White House last year. He pledged to take a tougher approach to China than the Bush administration did. He said the failure by Bush and Paulson to label China a currency manipulator was “unacceptable,” and he endorsed legislation to let US companies seek import duties to compensate for the advantage an undervalued currency gives their Chinese competitors.

But in both the April and the current October report, the administration declined to name China a currency manipulator.

Here’s the story from the AP: http://tinyurl.com/ygw5afp

Of course prices have risen.

We finally are back to manufacturing expansion following 18 months of contraction in the manufacturing sector. Supply chain pretty much destocked. Low inventories. Domestic mills operating at 47% of capacity. Global influences on scrap and raw materials. You need a program to follow this game. We’re providing you one with this edition of PMPA’s Material Impacts Report.

The prices of the raw materials that we track have continued to rise with double digit percentage gains over January with one exception: China Coke. Year over year, all prices are still down significantly.

- Aluminum: Up 18.65% from January

- Copper: Up 86.67% from January.

- Nickel: Up 27% from May, up 4.44 % since January.

- Steel Busheling: Up 26.67% from January.

- China Coke: Down 2.73% from January.

We have seen price increase announcements in addition to surcharge increases since our last report.

Details in PMPA’s Material Impacts Report.

![]()